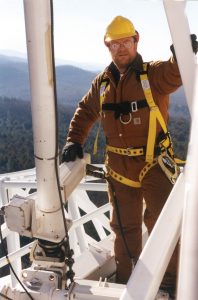

Green Bank Engineer Dennis Egan is nearly 400 feet above the ground at the end of the feed arm of the Green Bank Telescope. He is working on the motors that gently adjust the position of the telescope’s secondary reflector, a small dish that aims the GBT’s collected radio waves down into its receivers.

Removing the Focal Plane Array

At the Prime Focus of the Green Bank Telescope (GBT), technicians carefully separate the Focal Plane Array receiver from the cage. Its conical feed horn will then be detached, and the receiver will be carefully lowered to the ground via wires.

Lowering a Receiver

When a large receiver is removed from the Green Bank Telescope’s prime focus, it takes an unusual route back to the electronics lab: via wires. In this photo, the new Ka-band Focal Plane Array is too big to ride the elevators down the GBT, so instead, it is lowered carefully to engineers on the ground who have a truck waiting to bring it back to the lab.

Job with a View

Telescope technicians can enjoy the view when they’re working on the Green Bank Telescope (GBT), hundreds of feet above the gorgeous West Virginia countryside.

Hoists for the Painters

It takes years to completely repaint the Green Bank Telescope, and painters arrive every summer to keep this endless task going. The painters are suspended in these hoists beneath the backup structure of the GBT where they have 7,652 trusses to paint.

Painting the GBT

Each of the 2004 aluminum panels of the 2.3 acres of Green Bank Telescope’s surface must be scraped and repainted on a rotating schedule. It takes years to paint the entire GBT, and painters arrive every summer to keep this endless task going.

The paint on the GBT is a special blend that reflects sunlight, gives off heat, and its molecules do not give off radio waves.