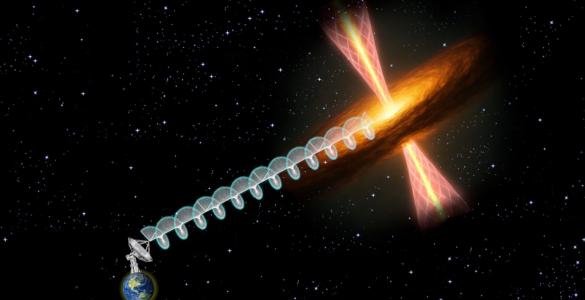

Who Operates the VLA?

To run a world-class radio telescope observatory in the New Mexico desert requires a talented staff. The Very Large Array and the Very Large Baseline Array need a spectrum of technically-savvy staff to care for their equipment, software, people, and science.

Antenna Mechanics

The antenna mechanics take care of the surface and structural aspects of the antennas. They play a major role in azimuth bearing changes, build prototypes for new equipment, and assist with transporter moves of the antennas and anything else that involves any of the physical aspects of the antennas.

Antenna mechanics spend a lot of their time up in the antennas. Wearng safety harnesses, required equipment for every technician who goes above the surface of the dish.

Antenna mechanics are also in charge of the paint shop. They have a self-contained building with an exhaust system for safety.

Array Operators

Array operators pay attention to multiple computer screens that monitor the health of the antennas, answer radio calls from technicians in the field, work with observers and scientists whose tests or observations are running, and field questions from tour groups that may be passing through.

Astronomers

In Socorro, a dozen astronomers help support the international users of the VLA and the VLBA through data reduction, project planning, observing advice, and on-site guideance. In addition, the scientists perform their own research projects.

Carpenters

The carpentry department is responsible for major projects, such as remodeling, as well as all the touch-up and repair jobs to walls and ceilings that can be required in a facility of this size. At times temporary employees are hired to help with major or seasonal projects.

Cryogenics Technicians

The technicians in the cryogenics lab build and maintain the refrigeration systems that cool the electronics inside the vertex room of the antennas. Helium gas cools the receiver systems down to about 15ºKelvin, or -432ºFahrenheit.

The technicians must work in a clean environment that sometimes them to wear white cotton gloves when handling the components. If oil from their hands gets on the components, it will freeze and act as an (unwanted!) insulator.

Drafter

A drafter keeps the site utilities plans and schematics for the buildings, vehicles, antennas, and workshops at the site up to date.

Electricians

The electricians are responsible for maintaining power to the antennas and all of the buildings on the site. They are called in any time a building is remodeled and when new construction projects are begun. They also maintain the site’s two diesel-powered generators. During “lightning season,” when power outages are common in New Mexico, the generators get a good work out, providing a consistent power source to the array.

Engineers

Engineers oversee, confer, design, and re-design everything from azimuth bearing changes to front-end receivers to software. Much of the design work happens in the offices and huge laboratory in the Pete V. Domenici Array Operations Center.

Fabrication of the diversity of specialized parts is a job divided by expertise, with small parts (such as amplifiers and mixers) being made in Charlottesville to large structural components (feeds and collars) being machined on site or in Green Bank.

Not everything is done on the computer-sometimes they have to resort to a pencil and paper!

Grounds Crew

The VLA grounds crew does a little bit of everything, from maintaining the walkways for the public, to planting trees, mowing, and many other “as needed” assignments, such as stabilizing the ground around a steel structure that houses the fiber optic connection from the arms of the array to the control building. They often use large pieces of machinery and heavy equipment but are equally talented in the wielding of shovels and brooms.

Machinists

Our machinists have over 100 years combined machining experience. They are called upon to make parts for nearly every sector of the observatory, from small electronics to large feed horn prototypes to latches for VLBA tape cases to exhibits for the Visitor Center.

The VLA antennas are unique: we can’t run down to a hardware store to buy off-the-shelf parts. Our engineers and design technicians create the drawings for the new items and pass them on to the machinists to manufacture them.

Usually the machinists make the part according to an autocad print and may never know exactly where it fits into the whole scheme of the antenna. Other times the machine shop participates in the research and design of our new antenna systems by creating the prototypes that are then tested, re-designed, tweaked, re-machined or re-created.

The shop has the equipment and expertise capable of machining parts from brass, copper, steel, stainless steel, fiberglass, and plastics. Without the machinists, NRAO would not have the scientific instruments appreciated by astronomers around the world.

Painters

Temporary paint crews are hired every summer. It takes nearly a month to clean an antenna, and another month to paint it, so only four or five antennas are painted each summer.

Painting the antennas is important for several reasons. First, it works to control corrosion on the steel. Secondly, it aids in the ability to point the antenna accurately. When part of the antenna is in the sun and part is in shadow, it heats, and therefore expands, unevenly.

The paint that we use contains a high concentration of titanium dioxide, which equalizes the temperature over a large area. With less difference in temperature there is less difference in expansion and contraction.

Public Outreach Officers

The VLA has a Public Information Officer in charge of VLA and VLBA press releases and media visits to those sites. An Education Officer manages tours, the Visitor Center and its Gift Shop staff, and educational programs to local schools.

Safety Officer

NRAO employs a fulltime safety officer to help ensure the safety of employees, visitors, and the equipment and facilities. Employees are trained on everything from CPR to safe driving to proper lifting techniques.

One of the most important safety procedures for anyone who is working on an antenna is the “lockout/tagout” procedure. Each person on the antenna must attach a lock to the switch that turns on and off the drive motor circuitry, so that the antenna is disconnected from its primary source of energy.

Servo Mechanics

A Servo Shop is responsible for maintaining the electronics on the 300-pound servo motors that point the antennas. Each antenna at the VLA and the VLBA has 4 motors: 2 for azimuth and 2 for elevation. These motors generally work against each other to provide precision pointing to less than 10 arc seconds.

The VLA motors have been running since the 1970s and are pretty robust. The VLBA antennas tend to be more sensitive to power glitches and often blow fuses. Our mechanics give the VLBA site technicians technical assistance over the telephone, if they need immediate servo help.

The shop has both a VLA and a VLBA simulator for testing the units before they are re-installed on the antennas.

The Servo Shop also works on ACUs-Antenna Control Units. The ACUs convert commands from the modcomps (computers that control the antennas) to electrical motor currents that point the antenna for the observer.

Track Crew

The track crew maintains over forty miles of double railroad track at the VLA. They use big machines and move a lot of dirt. Railroad ties must be replaced regularly. The original track was set into clay that has expanded over the 40+ years the VLA has been in service. Our crew has to lift the rails and ties, dig out the bad clay, and rebuild a more robust drainage system before re-installing the track.

Quality ballast, a heavy gravel material, is one of the most important ingredients in maintaining railroad tracks. It must be replenished, and occasionally totally replaced.

Transporter Crew

The transporter crew drive and maintain the two giant transporters that gently lift and haul our VLA antennas to new pads throughout the year and for maintenance. The crew must also coordinate with the antenna mechanics, track crew, servo techs, and others any time an antenna must be moved, whether it is being moved into the barn for routine maintenance, to another location in the array, or on to the support structure to change an azimuth bearing.

Warehouse Managers

The VLA has its own warehouse at the site, containing thousands of items used by people at both the VLA and the Socorro Array Operations Center. The warehouse managers are responsible for keeping up with all of it: shipping and receiving, ordering, organizing, taking inventory.

Welders

If it can be welded, VLA welders can weld it, using Metal Inert Gas (MIG), Tungsten Inert Gas (TIG), shielded arc, and oxyacetylene welding techniques as well as brazing and soldering. They can also do plasma welding and cutting, if needed.